Enhancing Product Aesthetic Appeals: The Role of In-Mold Decorations in Production

Enhancing Product Aesthetic Appeals: The Role of In-Mold Decorations in Production

Blog Article

Grasping In-Mold Decorations: Strategies, Trends, and Ideal Practices for Optimal Results

In the realm of manufacturing, the art of in-mold designs stands as a crucial aspect of product style and manufacturing. As industries consistently seek ingenious methods to boost visual charm and performance, grasping the intricacies of in-mold decors has become a vital ability set. From picking the best products to incorporating sophisticated design trends, the trip towards achieving ideal cause this domain name is diverse. By delving into the methods, patterns, and ideal practices that underpin successful in-mold decoration procedures, organizations can open a world of opportunities that not just boost the aesthetic appeal of their items yet likewise enhance manufacturing efficiency and reinforce customer engagement.

Material Choice

Material selection is a critical facet of grasping in-mold decorations, as it straight affects the top quality and toughness of the final product. When selecting materials for in-mold decors, it is vital to think about variables such as compatibility with the molding process, the preferred aesthetic outcome, and the environmental problems the item will certainly deal with. Thermoplastic products like polypropylene, polycarbonate, and abs are generally used for in-mold decors due to their flexibility and capacity to accomplish elaborate designs. These products use superb moldability, allowing manufacturers to create complicated shapes and patterns with precision.

Additionally, the picked material ought to possess good bond residential or commercial properties to make certain that the decor adheres securely to the substrate during the molding process. Bond between the product and the decor is critical for stopping delamination and making certain resilient aesthetic appeal. Furthermore, products with high warm resistance are liked for in-mold decors, specifically for products that will certainly be revealed to elevated temperature levels during their lifecycle. By very carefully choosing the proper material for in-mold decorations, manufacturers can boost the total high quality and toughness of their items, meeting the assumptions of both end-users and clients.

Layout Innovation

A crucial consider advancing the area of in-mold designs is the continual expedition and implementation of style advancement strategies. Layout advancement plays a vital function in enhancing the aesthetic charm, functionality, and general top quality of items made making use of in-mold design processes. By including innovative style elements, manufacturers can separate their items in the marketplace, attract consumers, and remain ahead of competitors.

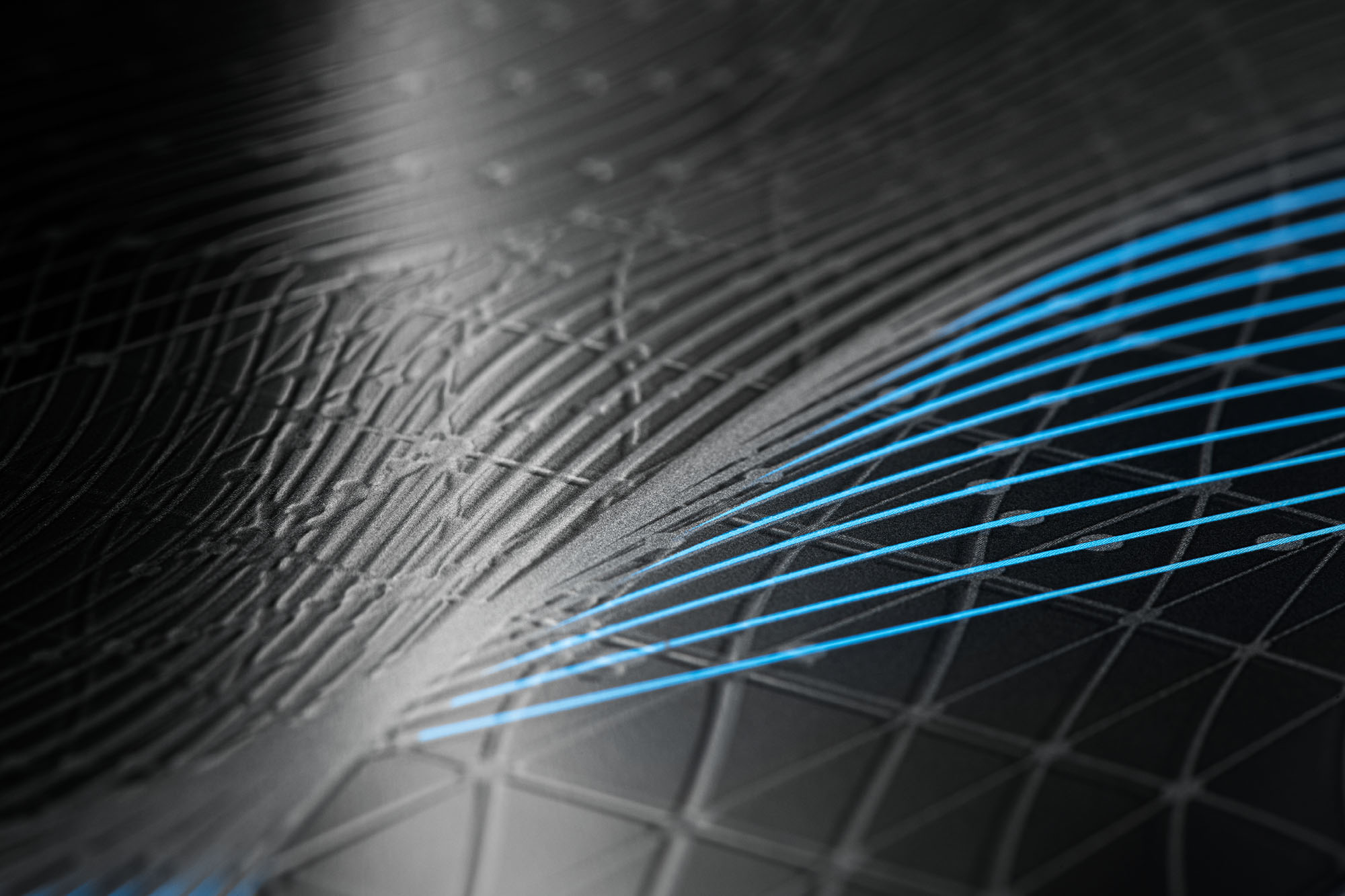

Among the key aspects of style advancement in in-mold designs is the assimilation of detailed patterns, structures, and graphics that were formerly testing to accomplish with conventional decoration methods. Advanced innovations such as 3D printing and electronic style tools enable developers to produce complex and comprehensive designs that can be seamlessly moved onto molded parts. Furthermore, the usage of vibrant shades, metallic surfaces, and special effects like gloss or matte appearances can further raise the aesthetic allure of in-mold decorated products.

Moreover, design innovation extends past looks to encompass practical improvements such as ergonomic shapes, incorporated attributes, and adjustable components that accommodate certain user needs. By embracing style innovation, suppliers can open brand-new opportunities for customization, creative thinking, and product distinction in the competitive landscape of in-mold decorations.

Manufacturing Effectiveness

Reliable manufacturing processes are important for translating the cutting-edge layouts created in the area of in-mold decors right into premium completed items that meet market needs and consumer expectations. In the world of in-mold decors, production performance encompasses different essential facets that contribute to the general success of the manufacturing process.

Automation not only speeds up the manufacturing process yet also enhances precision and repeatability, leading to a more high-quality and consistent end item. Overall, an alternative strategy to manufacturing performance is extremely important in maximizing the potential of in-mold decor techniques and accomplishing ideal outcomes in the affordable market landscape.

High Quality Control Measures

What are the key approaches for guaranteeing stringent high quality control measures in the realm of in-mold designs? Quality control actions are extremely important in in-mold decor processes to guarantee the manufacturing of flawless and high-grade completed items.

Utilizing advanced innovations such as computerized examination systems can likewise enhance the quality control procedure by offering precise and trusted information for analysis. These systems can detect blemishes that may be missed by hand-operated inspections, therefore boosting overall product quality and uniformity.

Normal training and advancement programs for workers involved in the in-mold decoration procedure can additionally add to keeping high-quality standards. By educating personnel on ideal practices, high quality expectations, and the importance of attention to information, business can promote a society of high quality consciousness throughout the organization.

Customer Charm

To improve the marketability of in-mold decor items, catering and comprehending to consumer preferences play a vital function in identifying their charm and success. Supplying modification options such as customized styles, shade variants, and textural aspects can substantially boost the appeal of in-mold decoration products.

Final Thought

In-mold designs provide a efficient and versatile method to enhance product visual appeals. that site By thoroughly picking materials, accepting innovative styles, enhancing production processes, executing quality assurance actions, and prioritizing consumer charm, suppliers can attain ideal results. It is critical for companies to consistently adjust and improve their strategies to remain competitive on the market. In-Mold Decorations. Mastering in-mold designs requires a holistic strategy that takes into consideration all elements of the production procedure to ensure success.

In the realm of manufacturing, the art of in-mold designs stands as a critical aspect of product layout and production. Style innovation plays a crucial duty in enhancing the visual allure, functionality, and overall high quality of products produced making use of in-mold decoration procedures.One of the vital aspects of layout innovation in in-mold decorations is the assimilation of detailed patterns, structures, and graphics that were previously challenging to achieve with traditional decoration methods.Reliable production procedures are vital for converting the innovative layouts established in the area of in-mold decors right into high-quality completed items that meet market demands and consumer expectations. Offering modification alternatives such as customized styles, color variations, and textural aspects can substantially boost the charm pop over to this site of in-mold decoration items.

Report this page